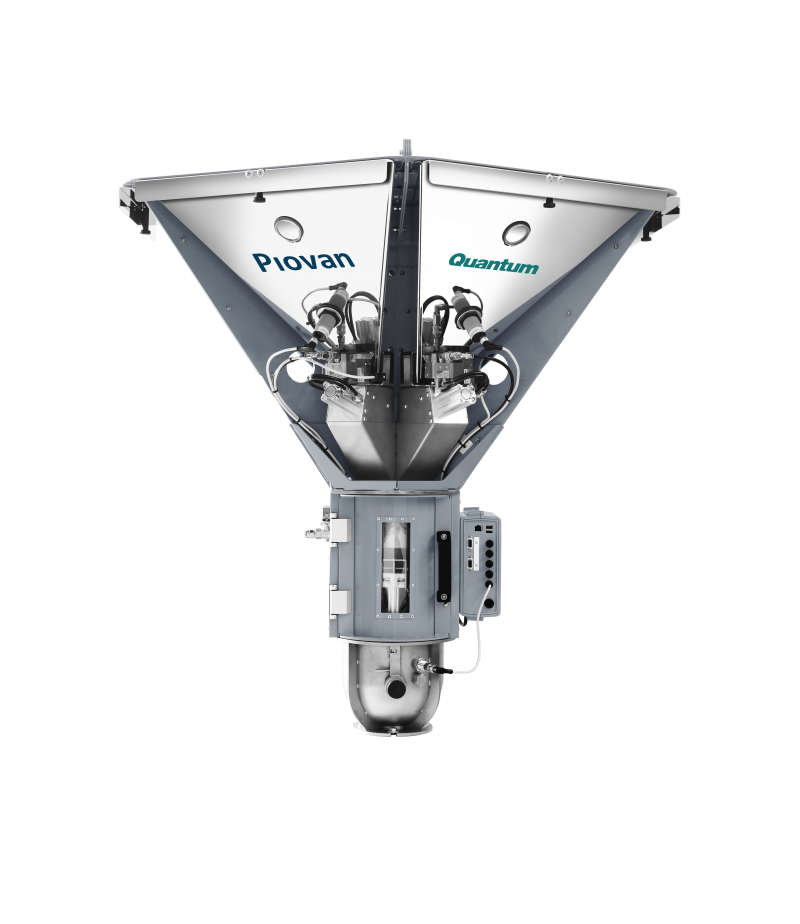

Quantum batch gravimetric blender

Technical information

Quantum embodies innovations that radically change the way injection moulding machines and extruders are fed with blends of materials (virgin, recycled, masterbatch and additives). These innovations contribute to increasing the efficiency of production, and feature improved design, innovative technologies and high performance components, which translate into concrete advantages for the user.

Quantum is utilised in all application environments such as Packaging, Automotive, Industrial and Electronics, Building and Construction, Textile, Furniture, Toys and Housewares, Medical and Pharmaceutical, Recycling and Compounds.

Benefits

● Immune to vibrations

● Expandable configuration

● Portability

● Quick material change

● Simplified cleaning operations

● Perfect omogeneity of the blend

● For all plastic materials

● With remote mixer

Its flexibility derives from two distinctive and unique characteristics.

a. All the surfaces that come into contact with the process material are stainless steel, usable also in the most critical environments, like those found in medical and food & beverage sectors. Low roughness prevents friction and permits uniform treatment of the polymer pellets, preventing the alteration of physical conditions. Quantum therefore protects the physical characteristics of the raw material, and thereby the quality of the plastic product.

b. Every blender comes with up to 6 dosing stations, which can easily be removed, for emptying or cleaning. Each dosing station is dedicated to a single ingredient— be it principal or additive; easy removal therefore aids material changes and enables optimal operating conditions to be immediately resumed without contamination from powder or residue. These interventions do not require the blender to be dismantled and can be done manually by an individual operator. The dosing stations can be used across all Quantum blenders in a factory.

Integration with WinFactory

The control system is designed for integration with WinFactory, the industrial supervisory software operating by application licence developed by Piovan, the outcome of consolidated knowledge in various application environments. WinFactory can interface all Quantum blenders in the factory for: sharing recipes, managing material and production batches, and tracking raw materials; these are fundamental data for product certification, in particular in food & beverage and medical-pharmaceutical environments.