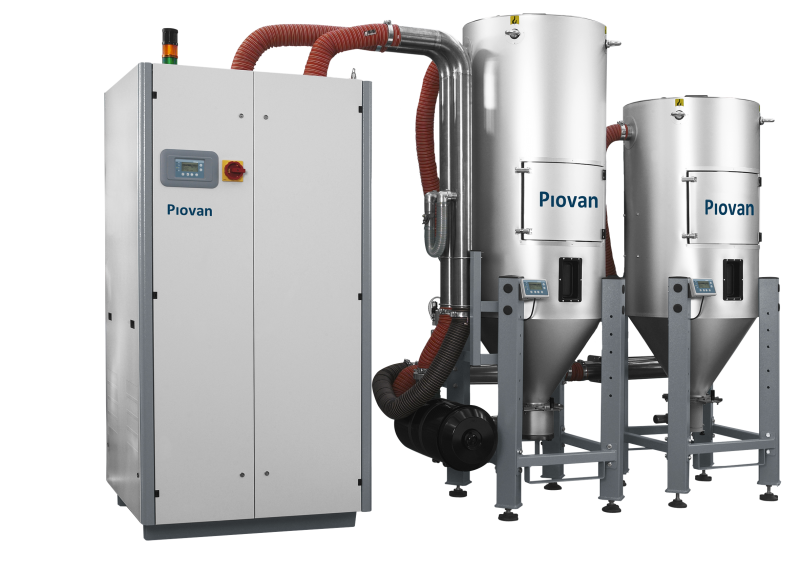

DP 619-624 double desiccant tower dryer

Technical information

These double desiccant tower models, with an airflow rate from 200 to 800 m3/h, supply air at a dew point lower than –55°C. The process air temperature can be set up to 150°C (200°C for the HT version).

Customer oriented solutions:

Precision:

Electronic control of the process temperature with self-tuning PID algorithm that ensures high precision.

Easy utilisation:

● Simple and complete operator interface

● Large display available in the operator’s language. It shows the functioning status of the machine as well as any possible alarm.

● On the main screen the following parameters of the dryer can be monitored: actual drying temperature, set-point, dew point value

Flexible and modular configuration:

The number of connected hoppers kan be extended at any time. The connected hopper capacity may vary from 300 to 2500 dm³; this with 1 drying hopper or in a multi-hopper configuration.

Intelligent Energy Supervisor:

● In accordance with the effective requirements of the processing machine, the IES system optimises and adjusts the energy utilisation.

● Intelligent Material Drying: prevents material thermal degradation or over-drying.

Benefits

● Single or Multi-hopper set up

● Temperature-control based regeneration cycle

● Dew Point Control

● Water Flow Control (only cooling water use if necessary)

● Automatic reduction of the process temperature

● Material consumption management

● Cooling stop

● Process airflow management

● Blowers and molecular sieves filtration system

● Solid state relays (SSR)

● Automatic set-up of the process air safety temperature

● Completely independent process air temperature safety control (temperature probe, power control and contactor)